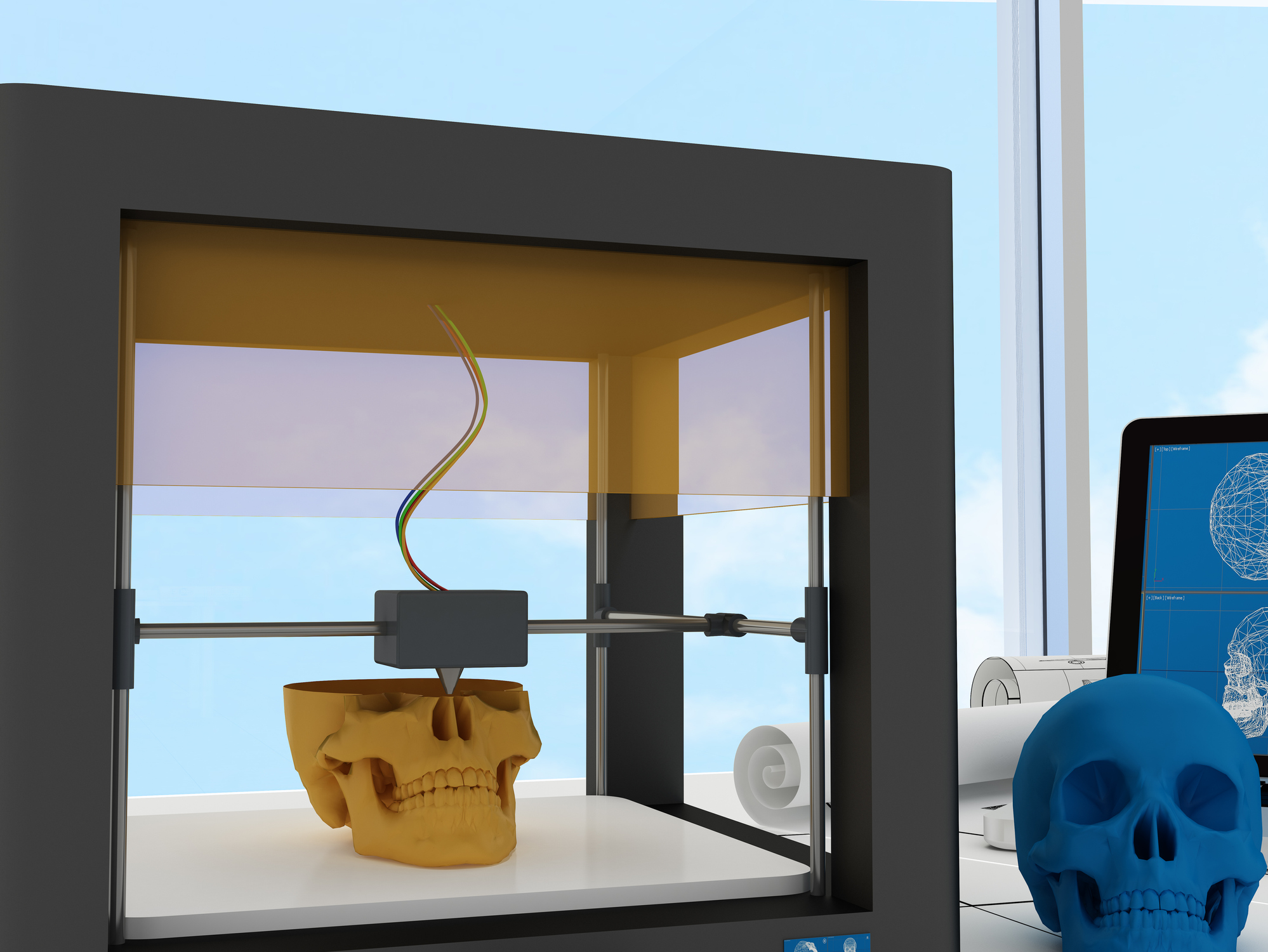

3D printing has become a major global player as technology advances and manufacturers increasingly choose to incorporate it in prototyping and production. 3D printing enables shorter lead times, reduced waste and customized products.

The medical and dental industry, in particular, has used the technology to its benefit. According to IDTechEx Research report, 3D Printing in the Medical and Dental Industry 2019 – 2029, a variety of devices can be made via 3D printing, including hearing aids, Invisalign aligners, and prosthetic limbs. The technology is so advanced that it allows for mass customization. Every patient is different, so personalization is key when it comes to designing comfortable devices that individuals need to wear for an extended period of time.

For example, 3D printing has made a large impact on the hearing aid industry. 3D printed hearing aids are created with digital precision and tend to fit better than those that are handcrafted. This is crucial because if a device is less than a millimetre off, it can be quite uncomfortable. 3D-printed hearing aids can also be made faster than handmade ones.

In addition to streamlining the process, 3D printing also boosts the manufacturing process, notes IDTechEx. That’s one of the reasons that it’s becoming more common in the dental industry. People using other medical devices also benefit from the technology because it makes life more comfortable and improves therapeutic outcomes.

Another advantage of 3D technology is its presence in surgical procedures. It can be used for the following: 1) teaching, 2) planning and visualization, 3) intraoperative surgical guides, 4) disposable surgical instrumentation, or 5) custom plates, implants, valves, and stents to be implanted into a patient.

3D printing improves efficiency in the surgical environment, which means a better outcome for the patient. In addition, 3D-printed implants are “durable, lightweight and customized to fit the patient for better functional and aesthetic outcomes.”

Believe it or not, 3D printing can also be used to create personalized medication by manufacturing pharmaceuticals, such as patient-specific pills. It can simplify things by streamlining the number of pills a patient must take or create dosages that limit unwanted side effects.

Thinking towards the future, 3D bioprinting has the potential for personalized organ implants through regenerative medicine. That’s pretty incredible.

With the use of 3D printing in the medical and dental industry, the future is promising for patients who require personalized devices (or organs!) to improve their quality of life.

It’s projected that 3D printing in the medical and dental industry will be worth over $8.1 billion by 2029.